THE BUILD PROCESS

HERE WE HAVE A COLLECTION OF ARTICLES FROM ‘THE BUILD PROCESS’

As the build process is an exciting part of becoming a owner in a brand new Riviera, we wanted to share this opportunity with you. We have fabricated a timeline, which explains in detail how the boats are built from start to finish (specifically the 5400 Sport Yacht).

With 40 years experience, Riviera has become one of the most experienced and well-known boating brands worldwide. Building up to 100 boats a year with skills and experience from more than 450 employees. Owners have the opportunity to see first hand, an elite quality of manufacturing like no other. Watching your boat being built from start to finish in Riviera’s state of the art factory is an experience everyone needs to be a part of!

TIMELINE -

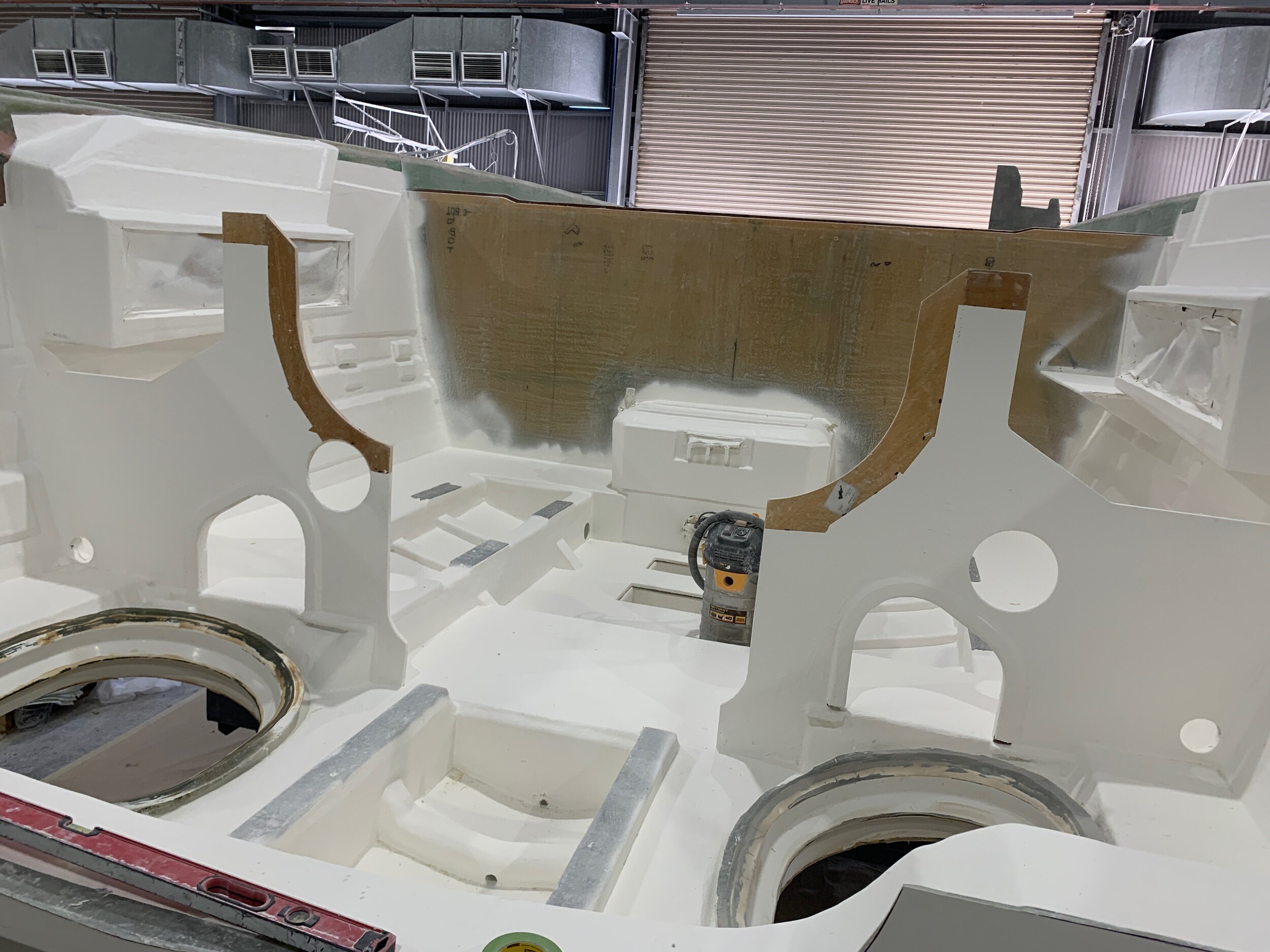

Lamination - The first stage of the build process is the lamination of the hull. In the meantime, the timber kit starts the manufacturing process. This includes cutting the timber out and assembling it, followed by the varnish process, ready for Fit-Out Two.

Cut Out Bay (‘Dusty Area’) - A procedure consisting of trimming the flange around the hull and cutting out any side hull windows.

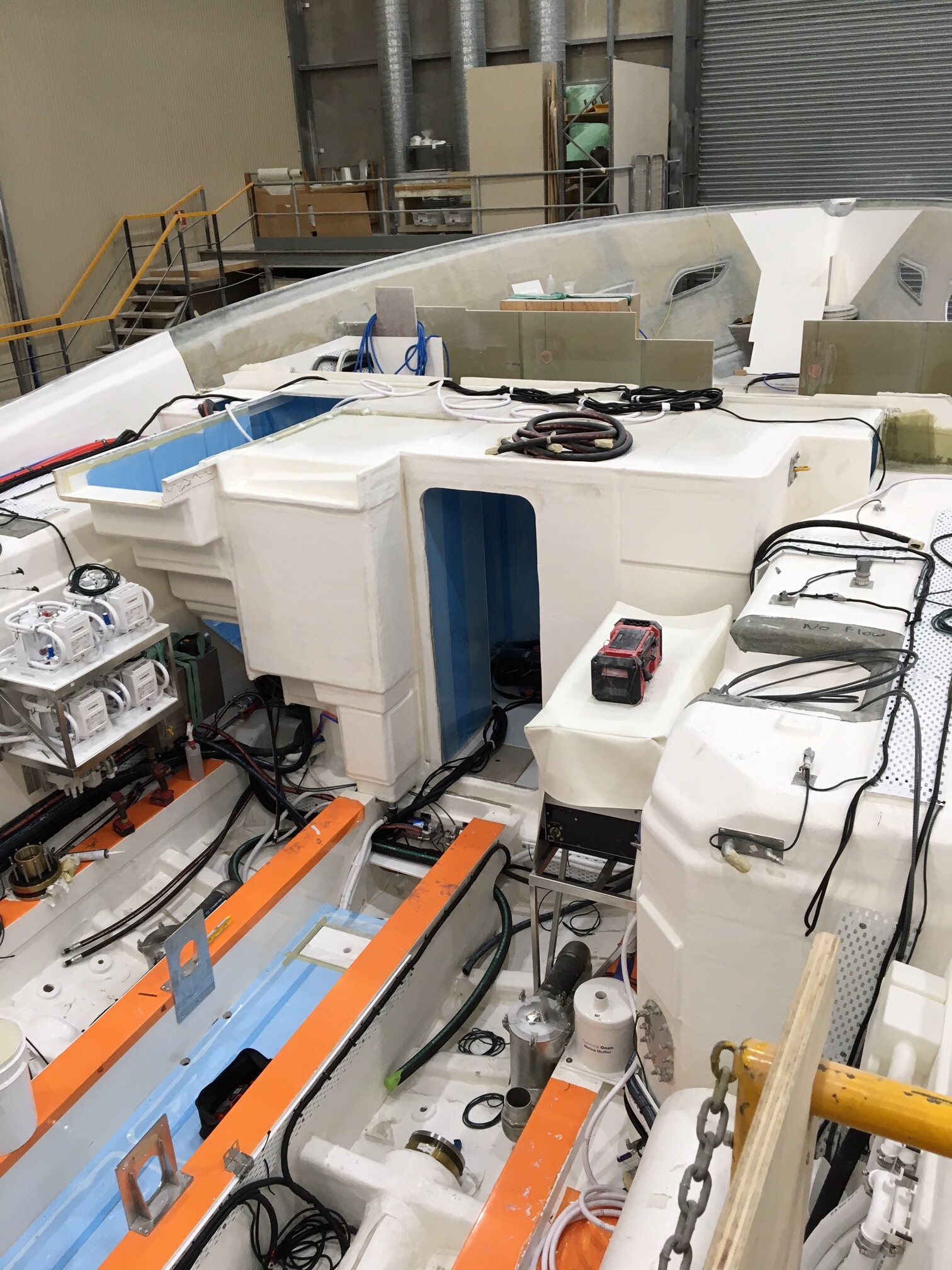

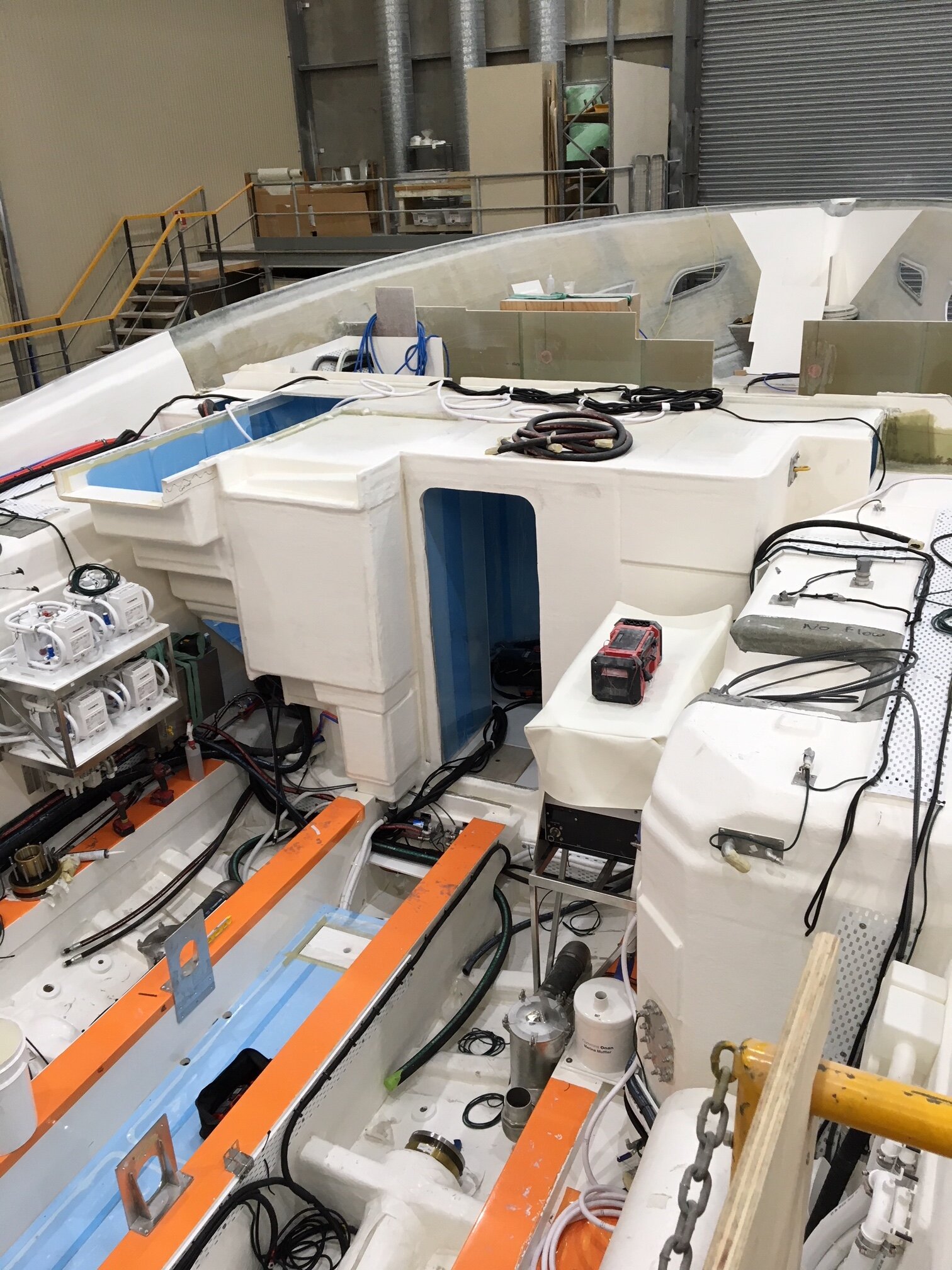

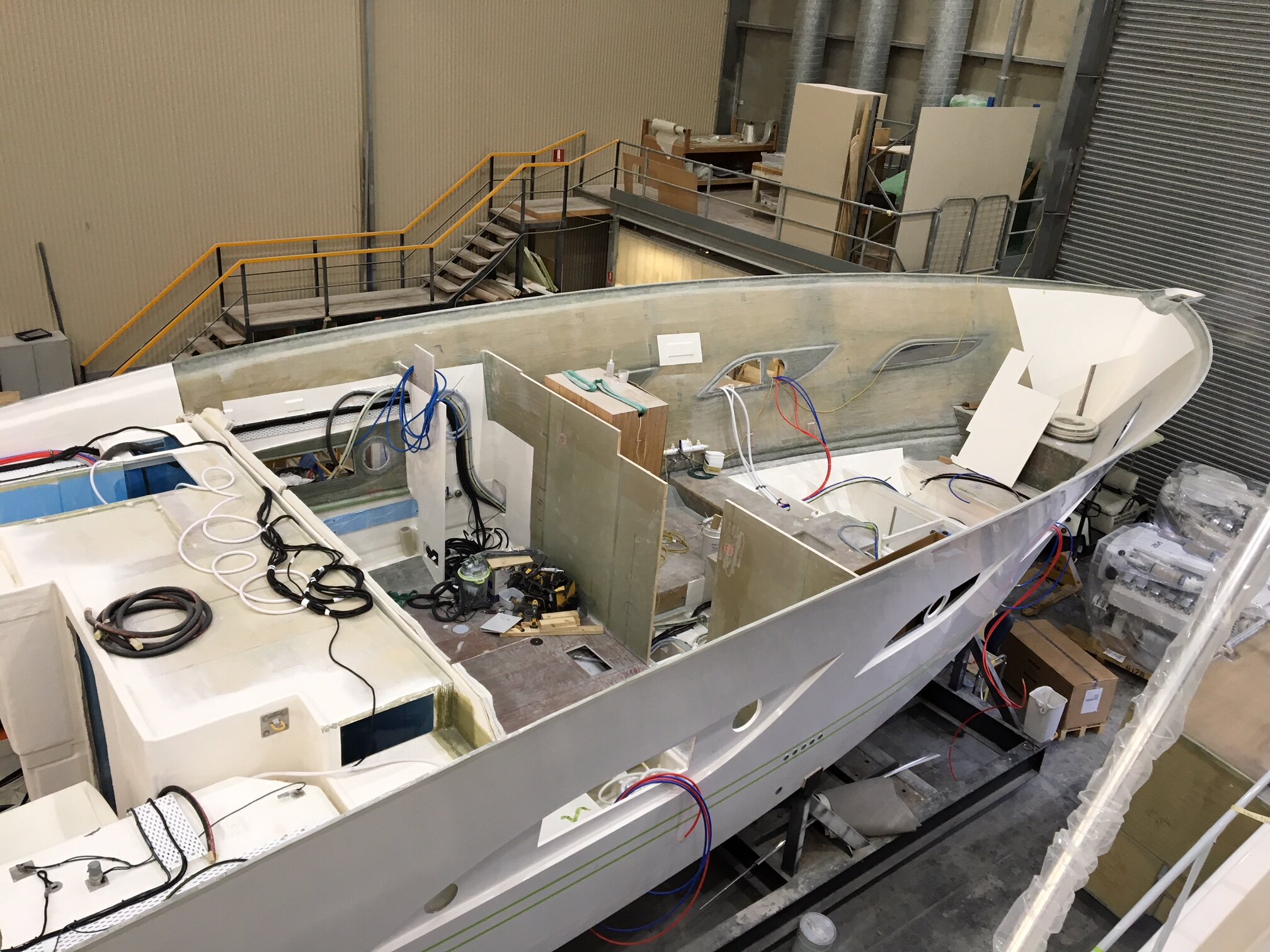

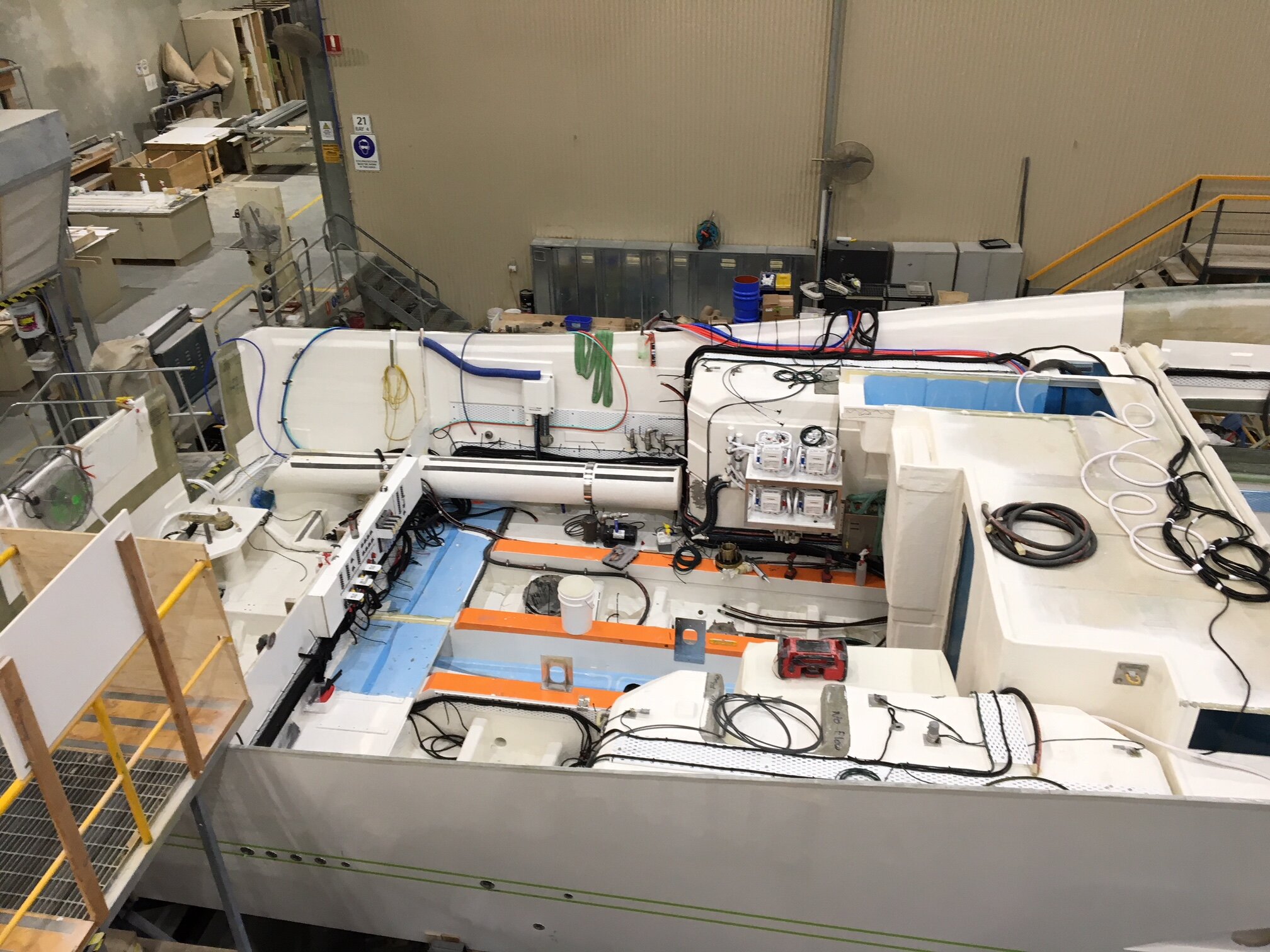

Engineering - The Engineering Stage refers to the assembling of the engine room. Components that need to be installed include gyro stabiliser, water maker, fuel system, batteries, water tanks, water pumps, generator, engines and drives.

The Deck - The deck begins lamination in the first or second week of the hull entering the engineering process. This is where additional plumbing and wiring is installed while the bow rail is also fitted.

Fit-Out One - Now it is time for the hull and deck to be joined. As this timeline is based on our 5400 Sport Yacht, the hard top will now be assembled with the electrical components including the radar dome, antennas and sunroof. Once assembled it is lifted on top of the deck. The Corian bench tops and bathroom shower floors will have begun production, so they are prepared and ready for Fit-Out Two.

Pre-Delivery - During this process there will be an electrical test to ensure that the wiring is safe. A leak test will also take place on the joins and windows. This involves sealing off every hatch, and window. A large panel is then placed on the back door with a fan that creates a vacuum inside the boat. A sprinkler then runs over the boat for a period of 6-8 hours to ensure that there are no leaks inside and the boat is fully sealed.

Fit-Out Two - Fit-Out Two involves the installation of the interior upholstery, all entertainment, electronics, helm chair, bench tops, flooring, appliances, and of course the entire timber kit. Once the interior fit-out is completed, the boat enters the paint shed where the hull is painted and the antifoul is applied.

Quality Control - The final stages of the build process includes sea trialing, quality inspection, rectification and wash.

Dealer Handover - This is where the boat is handed over to Boating Partnerships. After conducting our own quality control and having any issues rectified, our team then fits out the boat with additional items such as the tender, all kitchen utensils, additional appliances, spare parts and snorkelling gear.

Now is the time for owners to become familiar with their brand new luxury motor yacht. With training provided by Boating Partnerships, owners can have confidence that they will be able to control and manoeuvre their vessel comfortably.

On behalf of the Boating Partnerships team and managing director Tom van Vliet we are very excited to deliver this highly optioned magnificent 5400 Sport Yacht to its new owners.

“Taking part in the build process is allowing us to learn more about our boat as it transforms from an empty hull to our dream motor yacht.” - Peter and Anne (20% Owner of 5400 Sport Yacht Platinum Edition, currently in production)

Current owner…“We've been lucky enough to get the opportunity of observing the build from start to finish, which I think is very important. Even though you are a partner in the syndicate you still get a real sense of ownership while building your perfect boat. You have the ability to change and customise things during the process while gaining an understanding of what really is involved with building these magnificent yachts. Some would think building a boat with other partners would be difficult but in fact you end up with a better boat as different people have different ideas that I wouldn’t have thought of” - Roger Drake (part-owner of the 68 Sports Motor Yacht)

Below are a few of our vessels built and delivered over the last 14 months. These images show some of the stages of production, including lamination, engineering, fit out 2 and water testing. In our next monthly issue, we will be diving further into the production experience so be sure to be on the look out for it next month!

5400 Sport Yacht, Based in Pyrmont, Sydney, Shared between 5 Owners

68 Sports Motor Yacht that travels between The Whitsunday Islands, Gold Coast and Sydney every year, Shared Between 3 Owners

4800 Sport Yacht, Based in Rushcutters Bay, Sydney, Shared between 6 Owners

This experience allows our owners to visit Riviera Australia's state of the art 14 hectare site and watch as they handcraft these stunning and endearing luxury motor yachts. Not only is this a fascinating experience learning about how they are manufactured, our owners are involved in building their dream boat - with their fellow owners of course!

Peter and Anne (20% Owner of 5400 Sport Yacht Platinum Edition, currently in production)

"Having a boat currently in build has been a very enjoyable experience. I have been given the opportunity to not only observe the build but have input in deciding on options such as the Gyro and water maker. I believe these options were essential for use as well as adding to the resale value. This opportunity is just another reason to promote this experience with Boating Partnerships, presenting us with a real sense of ownership and pride. Taking part in the build process is allowing us to learn more about our boat as it transforms from an empty hull to our dream motor yacht. Our Riviera has just completed the engineering process while the hull and deck has just been joined. This experience is making us aware of how much goes into designing and building of Riviera motor yachts.

Another aspect we are enjoying is the opportunity to meet other owners of the boat. My wife and I had the chance to meet a co-owner during a factory tour and look forward to meeting the others along the way. Buying into a brand new build with Boating Partnerships was an easy decision. Having the ability to build the boat the way that you want while only paying a fraction of the price. Further, these vessels are Australian built with one of the worlds leading manufacturers.”